Electrification and renewable energy in Tianjin

Published on April 04, 2025

2 minutes

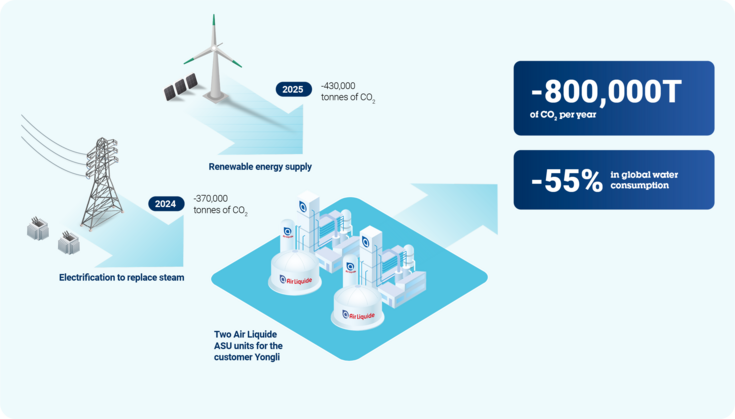

Using the right decarbonization levers depending on the site, in order to have the greatest impact – that is what Air Liquide has achieved in Tianjin, China. In less than two years, the Group has lowered CO₂ emissions at two oxygen production sites in a major industrial basin. Two key steps were at the heart of the project: both sites modernized their assets to reduce energy and are now sourced of low-carbon electricity following the signature of a multi-year Power Purchase Agreement (PPA).

Air Liquide’s decarbonization strategy includes three main levers: asset modernization, sourcing of massive amounts of low-carbon electricity and deployment of carbon capture and storage technologies at its plants.

In Tianjin, the Group was able to combine two of these levers in a project carried out with its customer, Tianjin Bohua Yongli Chemical Industry, as part of the renewal of industrial gas supply for two air separation units (ASUs) that produce 4,000 tonnes of oxygen every day, mainly for the chemicals sector. Step one was to electrify the site, which was previously powered by steam produced by coal based boilers. Besides reducing the carbon footprint by 370,000 tonnes of CO2 a year, this also cut water consumption by over half. Step two was accomplished at the end of 2024 with the signature of a multi-year PPA, paving the way for CO2 to be reduced annually by a further 430,000 tonnes starting in January 2025. In total, the two projects will bring down the carbon footprint by 800,000 tonnes of CO2 every year.