Renewable and low-carbon hydrogen for TotalEnergies’ Grandpuits biorefinery

Published on April 04, 2025

2 minutes

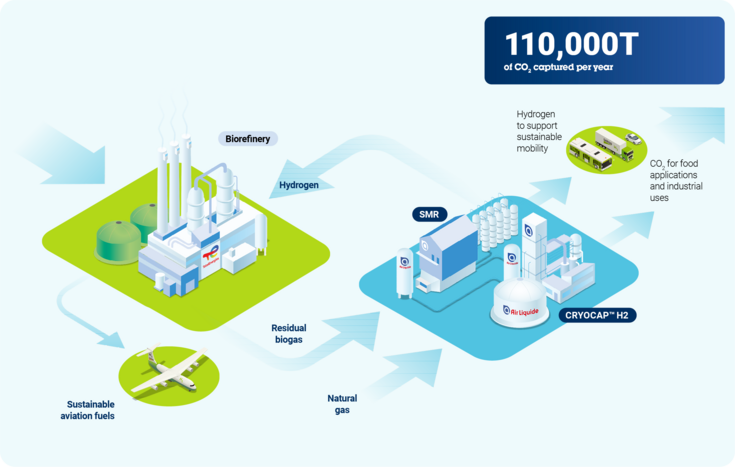

As part of the conversion of TotalEnergies’ Grandpuits facility into a biorefinery, Air Liquide is building a renewable and low carbon hydrogen production unit with an annual capacity of more than 20,000 tonnes. It will use biogases emitted by the biorefinery to partially replace the natural gas traditionally used and will integrate Air Liquide’s CRYOCAP™ CO₂ capture technology. The hydrogen produced will be used to produce sustainable aviation fuel.

Air Liquide has invested over € 130 million in a new renewable and low-carbon hydrogen production unit, which is helping reduce the carbon emissions of the TotalEnergies’ Grandpuits platform. The project integrates Air Liquide’s SMR-X™ and CRYOCAPTM proprietary technologies, the latter making it possible to capture up to 110,000 tonnes of CO2 every year for reuse in food and industrial applications. The hydrogen will be used to produce sustainable aviation fuel and could meet clean mobility needs in the Ile-de-France region. Through this collaboration, Air Liquide and TotalEnergies are pursuing a sustainable and circular economy approach, consistent with the goal of reaching carbon neutrality that both groups have set for 2050.

Following the signature of this long-term contract in 2022, another major project was announced with TotalEnergies at the end of 2024. Air Liquide will build, own, and operate a new renewable hydrogen production unit with an annual capacity of 25,000 tonnes to supply TotalEnergies’ biorefinery at the La Mède site in the south of France. This project will contribute to the emergence of a new renewable hydrogen ecosystem in the Fos-sur-Mer area, a major industrial basin for Air Liquide in France.